It is the leading brand of the group and offers solutions for every need for stretch wrapping machines with stretch film, ensuring maximum stability, high safety and optimisation of costs.

The complete range of TOSA stretch wrapping machines can satisfy every production request and guarantee performance of excellence, durable over time.

The secrets of excellence

- Design for low maintenance

- Maintenance 4.0

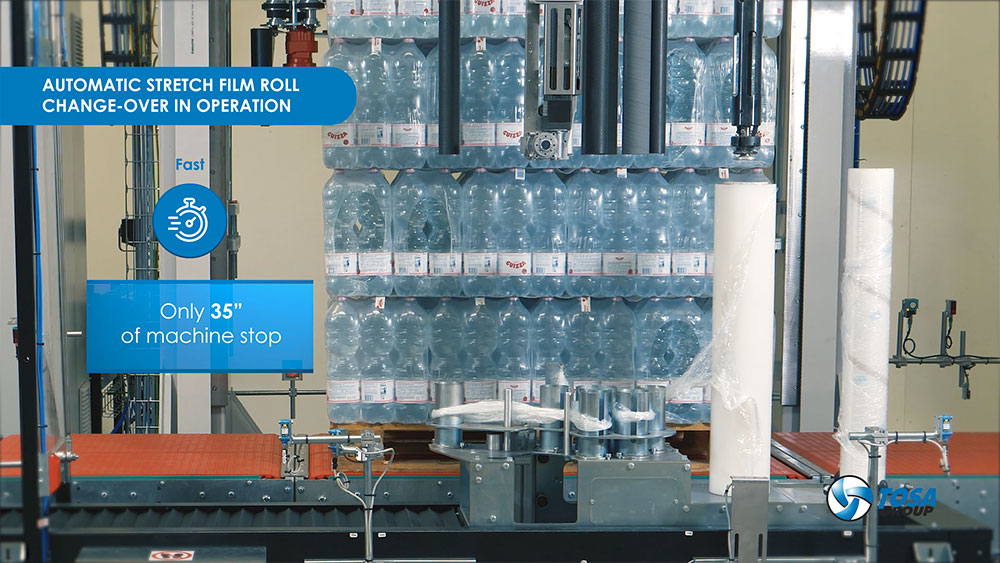

- THE FASTEST AUTOMATIC FILM ROLL CHANGE-OVER IN THE WORLD

- UNIQUE AUTOMATIC TOP FILM ROLL CHANGE-OVER

- Best containment force

- Smart wrapping technology

- CORNERS PROTECTION

- 750MM FILM ROLL

- Savitar

- Tailfree system

- Clever Rhombus

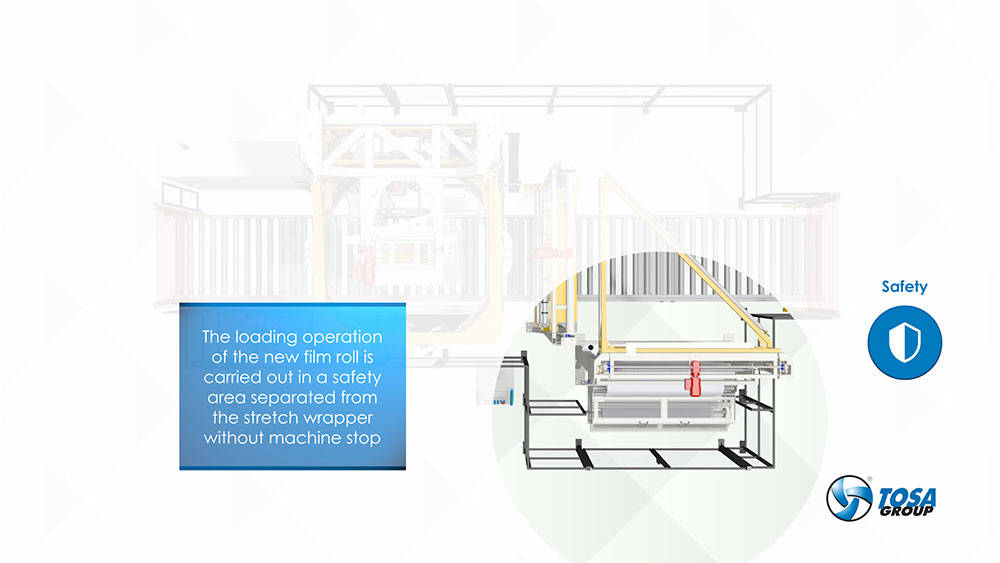

- SAFETY

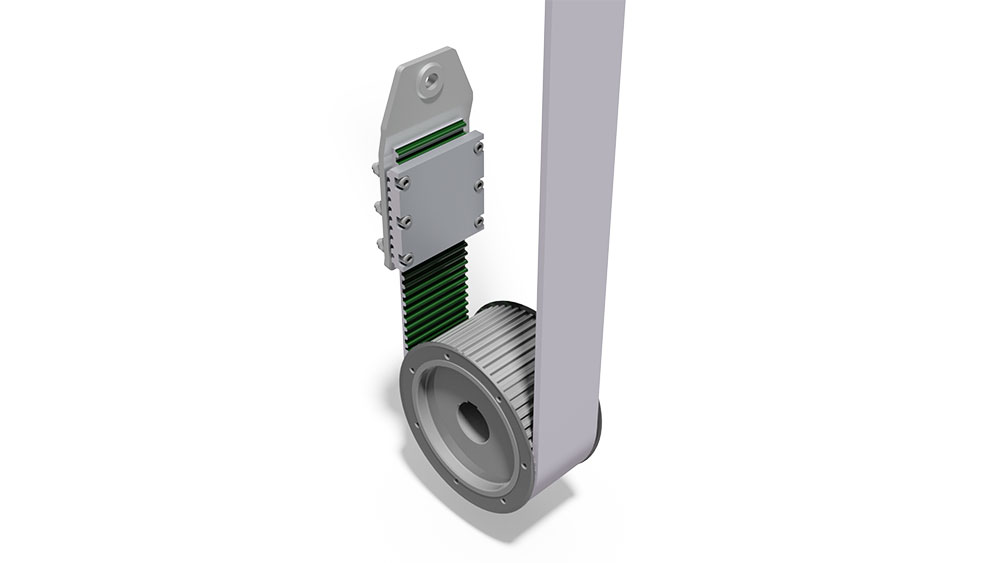

Our machines are conceived following the principle of the “design for low maintenance “philosophy which provides for the design of each device to guarantee minimal maintenance and optimise time saving, sustainability, safety and cleanliness. This setting allows a saving on the ordinary maintenance of the 75%. The elements where the philosophy emerges more are:

- Toothed belts, lubrication free

- Lifting group, pre-lubricated for life

- Sliding devices with direct motorisation

- Cable channel and identification of components and cables

- Centralised lubrication points

Like a forever young Peter Pan a Tosa Group machine doesn’t fear time and guarantees the least TCO, because maintenance is an integral part of the design. Our maintenance 4.0 approach includes:

Preventive Maintenance smart interface: Graphical interface that clearly guides the operator in the planning and management of the preventive maintenance to guarantee constant excellence and long-lasting performances. The machine indicates, through operative panel, when it is time to planning and to intervene with maintenance.

Predictive maintenance smart interface: Our machines check their effective operative conditions with a focus on engines, belts and pre-stretch carriages indicating, through operative panel, whether they notify any symptom that requires a little intervention which would prevent future maintenance operations. Carbon Footprint smart interface: Every time you need you’ll be able to verify in an easy way, through operative panel, the levels of air and energy consumption of the machine. Possibility to log and share data on management systems. Troubleshooting smart interface: Graphical interface that clearly guides the operator in the resolution of the malfunctions with a consequent time saving. The troubleshooting smart interface allows a saving of the 73% reducing:- Time for detecting malfunctions

- Time for detecting type of intervention required

- Machine downtimes

- Operator stress due to malfunction situation

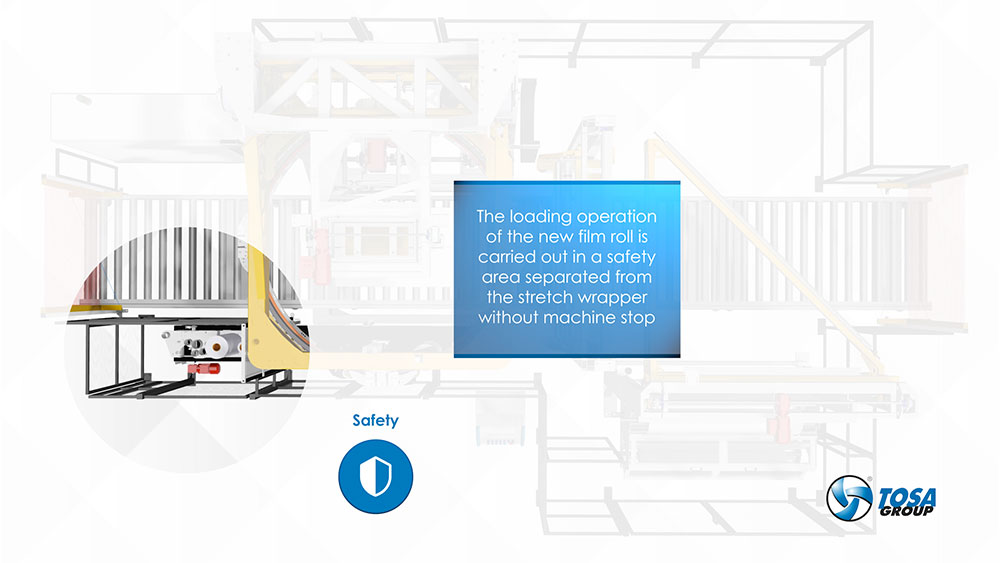

The fastest in the world with a complete replacement in 35 sec. without operator’s intervention, covered by international patent. Easy to use and reliable, it also guarantees the highest safety thanks to the position of the film roll loading zone in a security area separated from the stretch wrapper.

Optimisation of the production capacity with an average increase of 21.280 pallets per year.

Only completely wrapped pallet.

Unique in the market, we guarantee only completely wrapped pallet thanks to our patented device for film tail recovery. All the other systems in the market finishes the film roll leaving the last pallet not completely wrapped and after changing the film roll they have to repeat the cycle. All this produces:

- Film tails out of the wrapping, enemy of detecting systems

- Loss of time and costs increase for repeating the cycle

- Loss of effectiveness of the containment force (due to the over wrapping of the load)

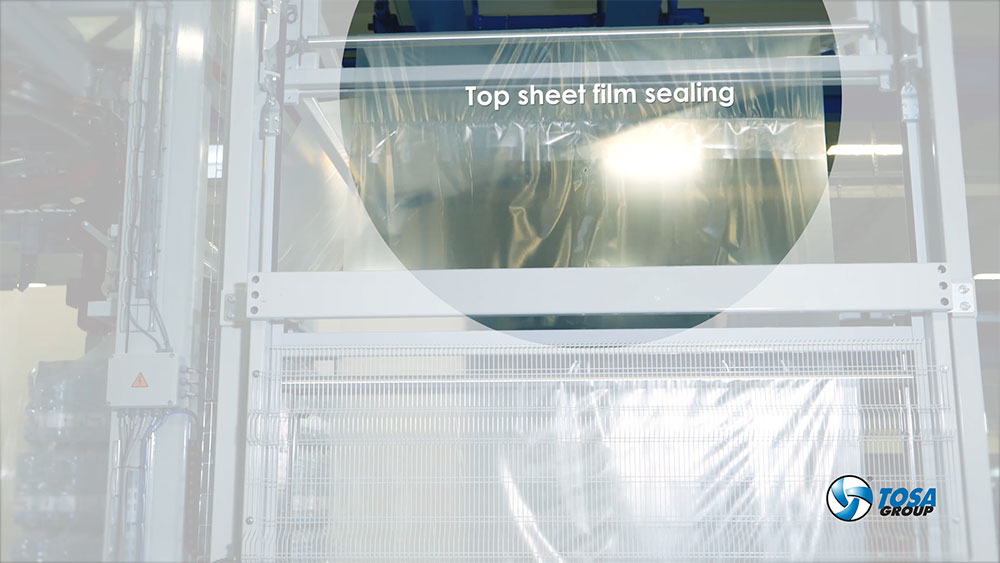

Unique in the world, we offer you automatic top film roll change-over to allow incomparable time savings. The only one and the fastest: replacing of the finished top film roll in 10 sec without intervention of the operator. Easy to use, smart and safety thanks to its positioning on the same side as the automatic film roll change- over in a security area without needing to stop the machine.

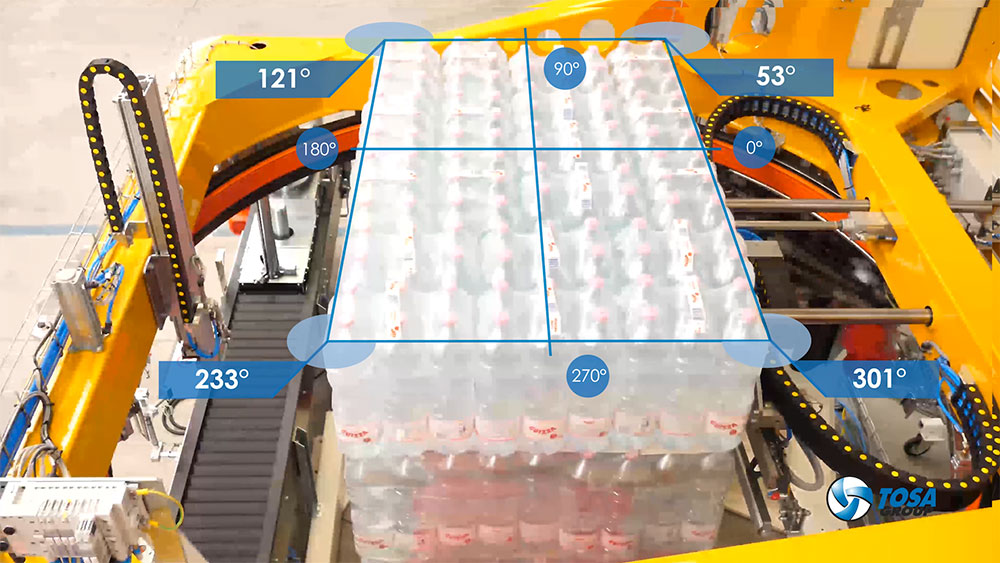

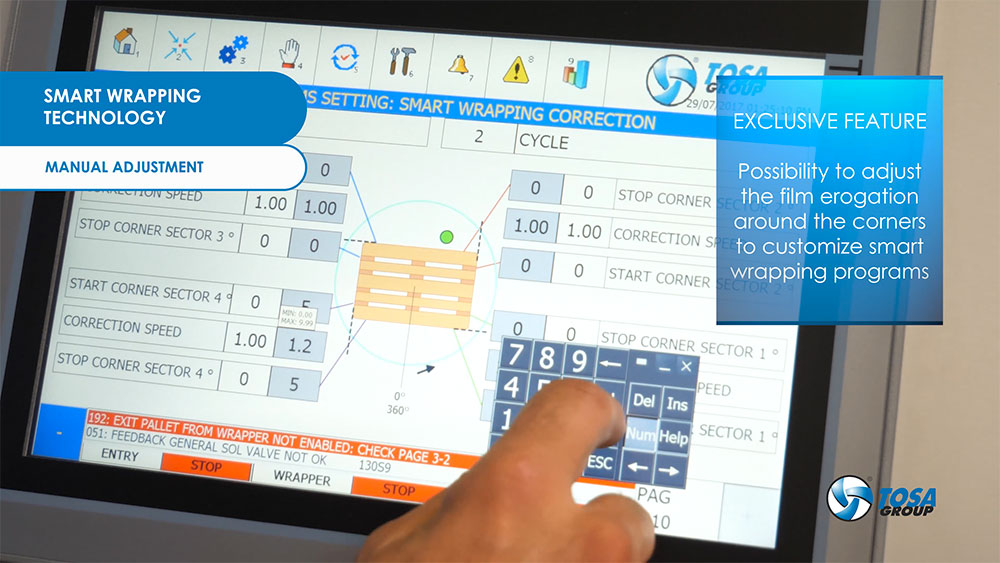

Smart wrapping technology allows to automatically optimising the distribution of the film during the different phases of the wrapping cycle to minimise the consumption of film and actively control the tension of the film in the corners of the load. The automatic detection system of the size and position of the palletised load improve the wrapping recipe adjusting it on that specific load. It’s possible to adjust the film feeding around the corners acting directly by operative panel.

The protection of the vertical corners of the palletised load is a central theme in the wrapping because it guarantees the integrity and the stability of your business. We are specialised in the application of the corner posts application and you can count on a great expertise in different kind of markets. We are able to offer proper solutions for every type of product and size. Our system is composed by automatic applicator of carton and by multiple storages, in different solutions for stocking corners up to six sizes. Possibility to load corners in the storage units without need to stopping machine.

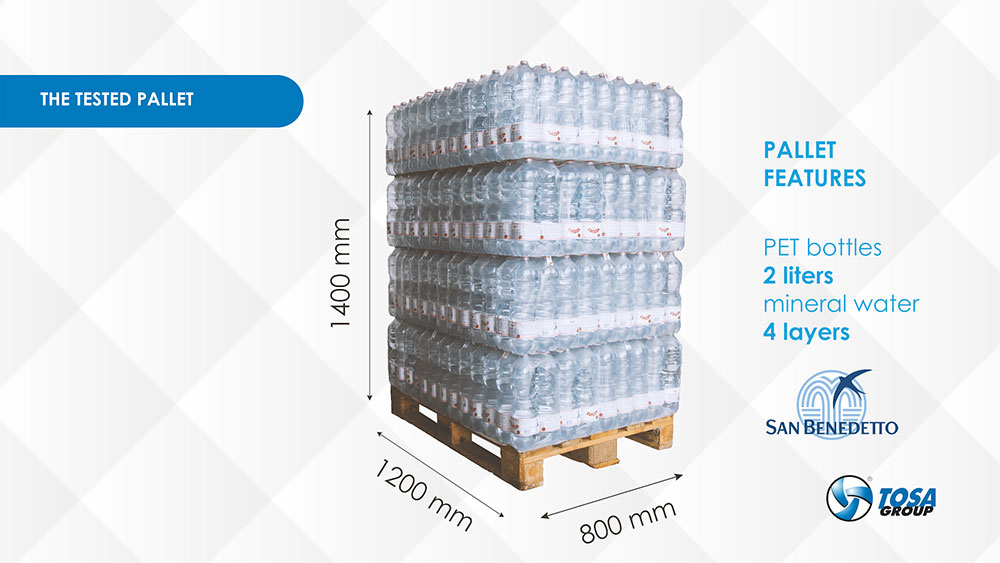

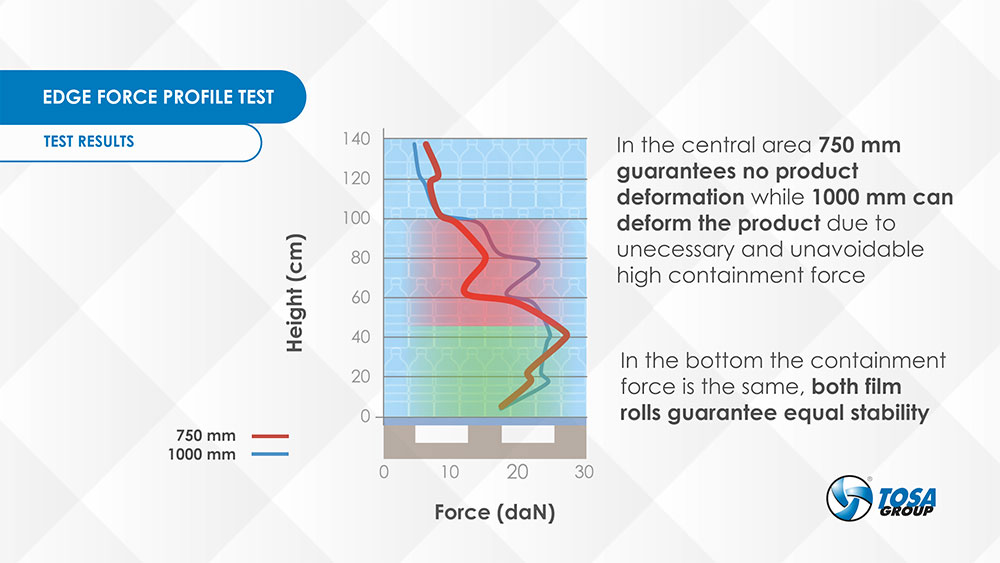

Our expertise and the laboratory tests realised with ESTL proved that the optimal solution for beverage market is the 750 mm film roll. Compared to the 1000 mm, used by the most, the 750 mm solution offers great stability, higher flexibility and a lower risk of deformation of the product. The less weight of the film roll guarantees a lower stress on the machine, energy saving and an easier film roll handling.

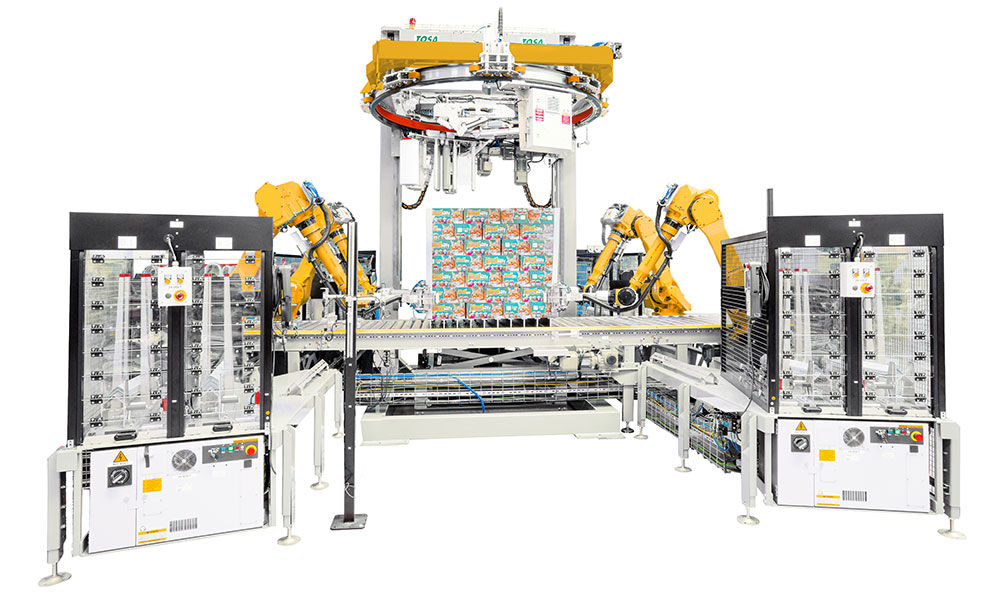

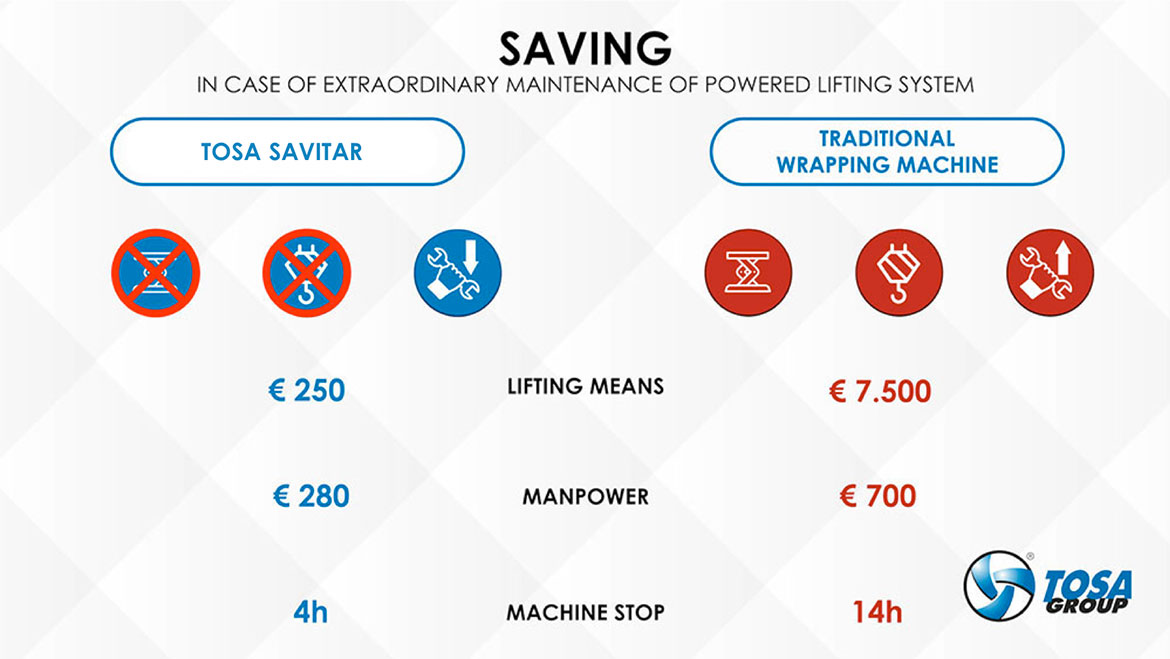

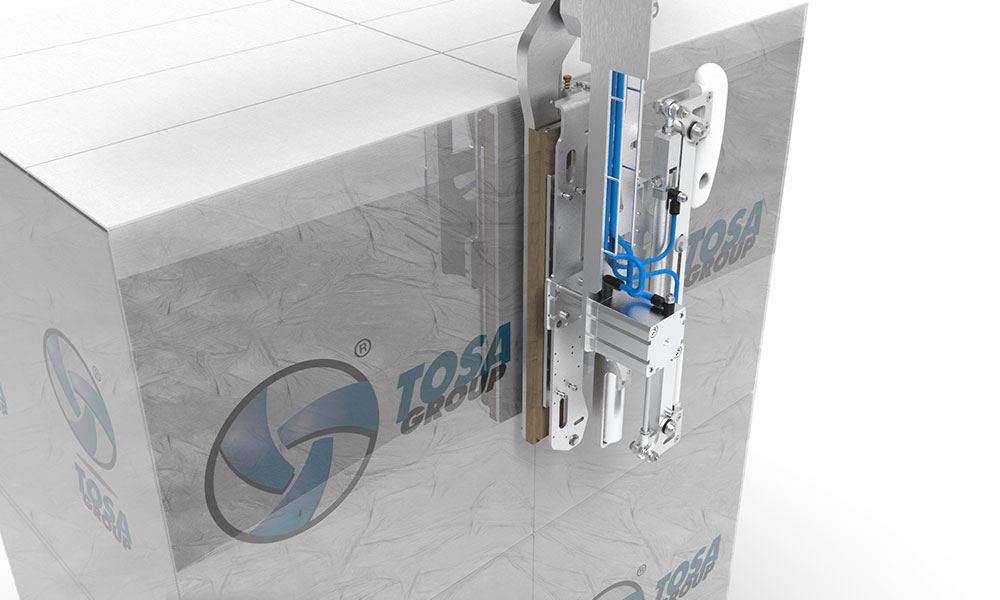

TOSA SAVITAR is the wrapping machine you were waiting for. The fastest in the market, achieving 80 rpm for production capacity up to 160 p/hour. It is the one and the only ring wrapping machine with grounded level motor positioning with consequent saving in ordinary and extraordinary maintenance. Savitar is fully designed for low maintenance and totally fail safe with anti-fall system and additional ropes to guarantee maximum safety for operators and loads. Tosa Savitar achieves unimaginable performance giving you much more than you can expect.

The latest-generation cutting/hooking/sealing TAILFREE system eliminates the possibility of pallets rejection at the entrance of the automatic warehouse due to film tails. Perfect shape scanning and thoughts-free storage

Thanks to the experience gained in the field of beer in which, because of condensate phenomenon , the macro-perforated film is mostly used, we have developed a new wrapping solution with standard film, focused on wrapping pattern. The Clever Rhombus solution is a wrapping configuration able to increase the air circulation, eliminating the condensation issue and bringing considerable benefits to our customers. This innovative program eliminates the usage of macro perforated film, offering various optimization:

- Less film consumption: - 27%

- More productive efficiency thanks to less film breaking during wrapping cycle

- Elimination of problem of scanning in automated warehouse

- Increased loads stability

- Costs optimization thanks to usage standard film (1,80€/Kg vs 3,50€/Kg) and no production stops

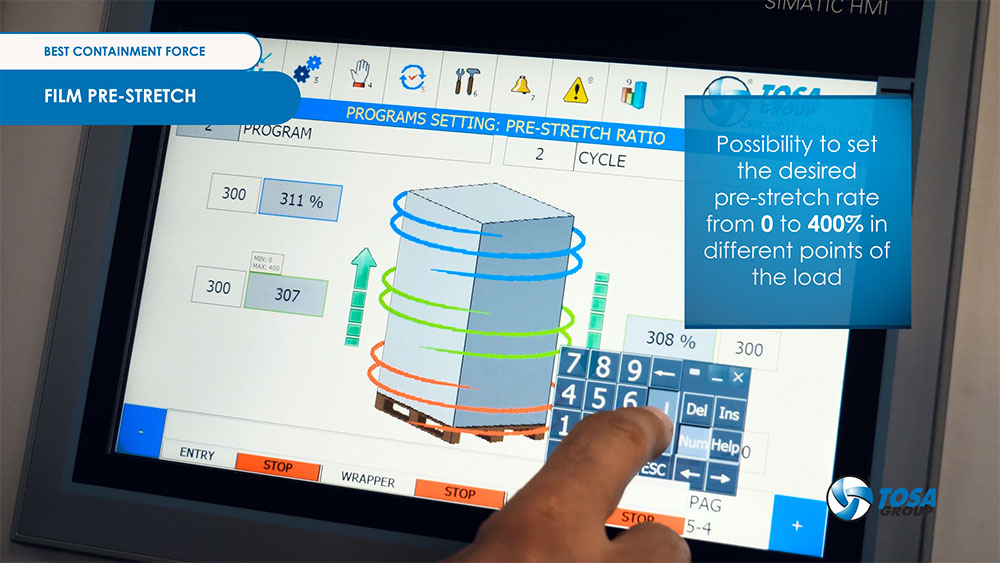

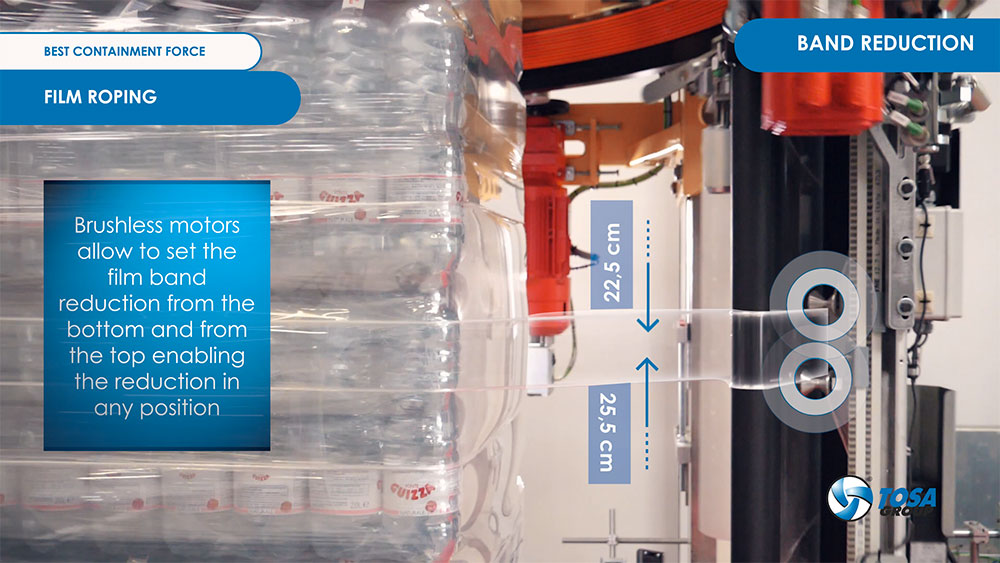

The containment force tells us the intensity of containment force exerted on each part of the load. Every load has specific needs of intensity of containment force for any different part. There are no pre-defined default recipes. The best solution is developed and studied on your load by wisely mixing all the ingredients:

- Pre-stretching of the film

- Tensioning of the film

- Film roping device

- Strategic positioning of the film

We strongly believe in safety and we want to ensure it at any level. Our machines must be completely safe and allow operators working in a harmless way. According to Directive 2006/42/EC on machinery, and pursuant to the application of the harmonized standard UNI EN ISO 12100: 2010, we carry out our risk assessment and determine the required Performance Level (PLr ) for each safety function thanks to the use of SISTEMA software. We ensure the safety of people, machines and loads by:

- Anti-fall systems for all suspended loads

- Safety light curtains/Photoelectric safety barriers placed –at least- at the minimum safety distance required by the specific standard (UNI EN ISO 13855: 2010)

- Doors equipped with interlocking systems according to the specific PLr to safeguard operator’s access to the machine working area

- Perimeter safety fencing with height, mesh and minimum installation safety distance according to the specific standard(UNI EN ISO 13857: 2010);

- Sectionable and padlockable power sources

- Machine control stations carefully chosen and managed, based on visibility

- Security procedure to manage the operator’s access to the protected area of the machine

Range

The broad range of TOSA machines guarantees the best response to every request for stabilisation and safety. Our three kinds of solution, turn-table, rotating arm and rotating ring are available for standard wrapping cycle, dust-proof cycle and water-proof cycle and they are customized to suit your needs. Every Tosa machine is tailor made because details and uniqueness make the difference, in your products and in our solutions.